2013-12-31 11:51:49

Innovative Packaging: The Brightest Bulbs on the Shelf

2013-12-31 11:51:49

|

Every year I look forward to doing a rundown on the latest launches from some of the beauty industry’s Top Packaging Innovators. For a bit of a cross-pollination approach, I like to start by researching other categories to discover what great new introductions have taken place and what their effect on beauty may be.

The automobile industry has frequently made its mark on personal care packaging through techniques such as colorization and finishes, as well as the successful combinations of materials and shapes. A recent concept in car manufacturing may influence packaging designers to further take up the challenges of recycling. Roughly 85% of the materials to be used in a new model Kia Soul will be designed for recycling when the vehicle reaches the end of its drivable life. Plans are for the car to also feature an all-electric engine, which will further shrink its environmental footprint. (Please stay tuned for our January 2014 article on one of Aveda’s package recycling programs.)

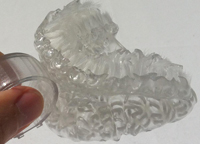

Blizzident is a custom-tailored 3D-printed toothbrush that promises to clean teeth by just biting and grinding for six seconds. |

When it comes to packaging for pharmaceuticals, there are many similarities with beauty—including safety issues concerning expiration dates. An idea for pill packaging recently surfaced as a way to let consumers know at a glance whether their medication is safe to swallow. The packaging is designed to change color as the efficacy of the pills starts to fade. A similar concept has been applied to tags on shower products such as sponges, which can tend to get funky after a few weeks in a damp bathroom environment. (For more info, please see www.beautypackaging.com/articles/2013/10/online-exclusive-a-better-body-scrubber-with-funct)

And then, there’s the virtual toothbrush, which not only saves time in a daily routine, but provides quick customization and utmost efficiency. With no actual resemblance to a standard toothbrush, the Blizzident custom 3D-printed “toothbrush” promises to clean your mouth in six seconds, and is custom-made for a perfect fit. Each brush starts with an impression or 3D-scan of your teeth, which is then uploaded to Blizzident for manufacture of the toothbrush using 3D printing. (Virtual techniques are also on the rise for cosmetics packaging, as you’ll see in this month’s feature on Package Development in this issue.)

Innovation, inspired by the ordinary and the extraordinary, remains at the heart of the beauty industry, whether with personal care, fragrance or color cosmetics. And packaging often serves as the key conductor for interpreting innovation to consumers. From clever bottles, caps and cartons, to evolved dispensing systems, compact sizes, captivating decorating techniques and even new gestures, the competitive drive for “newest,” “most effective” and “most desirable” has never been stronger.

Dr. Benjamin Punchard, senior global packaging analyst, Mintel, says, “Innovative packaging can be make or break.” |

“Packaging has always been important in beauty, and for those brands wanting to stand out from the crowd and offer consumers something more, then packaging is more often than not the way to do this,” says Dr. Benjamin Punchard, senior global packaging analyst, Mintel. “If a brand puts something new on the shelf, it is the packaging that draws in the consumer in the first place. So innovative packaging can be make or break.”

Dr. Peter Luebcke, Sagentia, says personal care packaging has always been a major contributor to new innovations in the packaging industry. |

Dr. Peter Luebcke, head of personal care at global technology advisory and product development company Sagentia, feels that the category, itself, inspires the packaging. He says personal care has always been a major contributor to new innovations in the packaging industry “due to the sheer diversity of functionalities required to contain, display and dispense its contents.”

During 2013, Dr. Luebcke says key areas of development have included improvements in airless packaging to keep air-unstable ingredients “fresh,” innovative releases in the mix-immediately-before-use area and also in personalization, where smart packaging is being used to help the consumer understand their particular skin care needs and apply the product accordingly. In particular, he cites the following examples of “notable innovations” reflecting these trends:

The Ioma Youth Booster enables personalized skin care based on the packaging’s measurement capability. |

• The Ioma Youth Booster, skin care with built-in diagnostics, enables personalization based on the packaging’s measurement capability. Dr. Luebcke says this trend has been commercially validated by Unilever’s move to acquire a stake in Ioma.

Aptar Beauty + Home’s Serumony, is an innovation dedicated to beauty elixirs, radiance-boosters and youth serums. It combines the beauty of a sophisticated package with the practicality of a high-tech pen. |

• Aptar’s airless stylus pen, Serumony, offers maximum protection of the formula from air degradation, and also enables precise dosing and placing. (For more on this pen, please see the article in this issue.)

•Further and more ingenious steps prevent counterfeiting of high-end beauty products, such as IdentMarker developed by Rathgeber, which uses solid-state materials that give a unique optical spectrum.

Dr. Luebcke says, “These exciting innovations in personal care packaging have achieved game-changing advances in the ways that packaging interacts with its contents and with the consumer.”

But while Dr. Luebcke’s examples shine, how many beauty packages are truly innovative? It depends on how you define the term. Innovation seems to encompass everything from a great design to a time-saving feature, a two-in-one product, or even new ways of doing business. Today, innovative thinking lends itself to every part of corporate planning and product development.

Innovation Defined

Darren Eade, vice president of sales, Kemas USA, admits: “It’s very hard to come across any ‘true’ innovations these days. Most of what we see are rehashed ideas that are simply packaged in a different way.” He says, “For me, the only criteria that defines an innovative package is when it’s never been done before and is considered truly unique.”

Eade says that most of today’s trends lean toward one of two main aspects: decorative effects and delivery systems. “There are only so many shapes that can be achieved,” he says, “therefore, there is not much you can do as far as calling something truly innovative. So we’re having to focus on the areas where we can really make a difference.”

For Kemas, this means a primary focus on innovation is currently based not only around new packaging concepts for lipsticks, but also around unique decorative options.

John Pyrzenski, sales director for HCT Group, agrees that innovation is a subjective term. He tells Beauty Packaging: “Improving the performance of a common packaging profile is just as paramount as developing a new delivery system or new technology platform. As long as it is a better solution, then it is considered innovation.”

For instance, says Pyrzenski, “Versatility in common packaging is in demand, whether through decoration, design or delivery. The ability to utilize a proprietary package across multiple SKUs while creating a unique user experience seems to be a common trend in design direction.” Pyrzenski says HCT is currently developing lines of packaging based on this concept.

At Arkay Packaging, Laura Carey, director of sales, says innovation relates to current trends such as new coatings, special effects and textures.

Delivery Systems/Applicators

As mentioned, delivery systems is a prime area for innovative products to emerge. So too are applicators and accessories.

HCP’s Comb End Mascara features a comb that can be accessed by sliding a button. |

One case in point: HCP recently introduced a new accessory to enhance the art of one-handed mascara application. Sue Pickford, creative marketing manager, says, “The idea is a simple but very effective, integrated mascara comb in the cap of a traditional mascara applicator.” After applying mascara, the user simply replaces the cap back onto the bottle and then activates the comb by pushing the slider button on the side of the cap. Pickford says the exposed comb can then be used to sweep and separate the lashes, stretching them to their maximum and delivering a double defined finish. When done, the comb is then retracted back into the applicator pack by sliding the button to its original position. The Comb End Mascara is currently available for use with HCP’s all plastic 55G mascara pack, although the design can easily be transferred to HCP’s other mascara packs as well.

With skin care remaining one of beauty’s top performers, new-to-market delivery systems and applicators are as sought after as new, efficacious formulations.

Cosmogen is known for its wide variety of applicators for skin care, including brushes. Charlotte Clabaux, the company’s marketing manager, says they have seen quite a few trends from brands looking for innovative applicators, with delivery systems at the top of the list. She says customers want functionality as well as practicality. Cosmogen offers this in its 2-in-1 combinations, including: a pack and applicator with a multifunctional brush/applicator for different uses (such as precise dispensing, scrubbing, cooling effect, massaging); ergonomic and time-saver solutions; and airless tubes with an on/off system. She says sensory effects during application are in demand, such as smoothness, micro stimulation, cooling effects and scar treatment.

Development of advanced applicators that aid in formulations penetrating the skin has also become a priority. At Lombardi Design & Manufacturing, Jack Albanese, director of new business development, says skin care is synonymous with innovation. Lombardi has partnered with Nanomed to bring to market a technology that drives product deeper into the skin through the use of microstructures embedded on a silicon chip.Albanese says, “When placed on a dispensing tip or applicator, they act to temporarily compromise the skin’s surface providing a clear path for treatment formulas to get into the skin with significantly enhanced results.”

Aside from the aesthetics and enhanced functionality of delivery systems, Dr. Punchard points to innovations that highlight practicalities: the compressed aerosol launches in the UK by Unilever for the company’s female deodorants (providing the same functionality but with much reduced packaging); and secondly, the dual aerosol hair colorant (now launched across several brands worldwide) that completely removes the self- mixing step and enables the product to be used as a when-needed rather than as a single application.

Deco Reigns (compact case)

A reflective, wet-like appearance has been created through a combination of metallization and spraying techniques pioneered by Kemas. Beneath the decoration is a standard plastic compact. |

Crackle, dewdrop and spider web effects are a few examples of Kemas’ innovations. Eade says, “The crackle effect is our latest decorative creation whereby we use a proprietary spraying technique coupled with a unique ink compound.”However, he adds: “Our most recent innovations can only be presented to the public by personal request.”

Brushes from Cosmogen include these, with a 3D effect/hologram on the handles. |

But while decorative techniques can attract consumers in stores, when it comes to packaging design for items sold online, the strategy may call for a different type of forward-thinking approach.

Mintel’s Dr. Punchard says, “I think that Internet sales have changed the way that designers think about packaging. If the consumer can’t pick up the pack to read and you can’t be sure that a website will show anything other than front of pack, then that front of pack becomes a very important billboard. I’ve seen the removal of clutter and a focus on clear simple front of pack statements. Also there seems to be a move away from using photo imagery on packs.” On websites, he says, this can be accommodated elsewhere on the page without being on the pack, and simple graphics are more likely to reproduce well on screen.

Dr. Punchard also says that advanced technology has fostered a reverse in certain brands’ thinking that consumers crave the reverse. “I think that there is in fact a bit of a computer/automation/brand backlash that is driving the trend toward small brands/small batches and hand made/artisanal products,” says Dr. Punchard. “For these basic pack types, simple graphics and letterpress or screenprint style graphics bring an element of craft to the packaging.” But, ironically,” says Dr. Punchard, “many of these smaller brands are reliant on the Internet to reach their consumers.”

Caps, Closures and Compacts

Metals and metallics, with their shiny attractiveness, add greatly to packaging’s allure, and have inspired a number of new techniques for caps and closures, as well as compacts.

Innovative caps draw lots of attention at Lombardi, where Albanese says, “We continue to see a need for fragrance caps with free flowing, organic shapes. Our most recent example is the metallized bow we produced for the Victoria by Victoria’s Secret fragrance.” The metallized bow is married to a metallized shoulder piece and a Surlyn cap, also produced by Lombardi.

Albanese says the bow was created using specialized computer-aided design software and hardware installed at Lombardi. “Our design engineers sculpted the free-flowing bow with an electronic stylus in midair to make the bow appear as natural as any fabric would be—except our part is a rigid, injection-molded piece of art.” (For more on this design, please see the article in this issue.)

Closure supplier C+N Packaging has followed the trend for metallic closures in combination with clear and glass-like aspects. Mairi Young tells Beauty Packaging, “Some time ago, C+N Packaging recognized the growing trend toward metallic closures and to that end, we vertically integrated our molding operations with in-house metallization in the USA and Poland.”

The upper part of the cap (from C+N) for Avon’s Passion fragrance is made of Surlyn for a glossy glass-like effect. |

“In fact, says Young, “C+N pioneered the glass perfume stopper look for Juicy Couture and we continue to meet customers’ needs.”

Another innovation for C+N, according to Young, is silk screening on a UV spray to give a smoky look such as that for Ermenegildo Zegna’s Uomo. “This technique required the expertise and teamwork of many leading suppliers worldwide,” she says.

HCP’s Pickford says they recognized the “primal allure of metal as the eternal trend for premium finishes,” which led to the development of Magnum, a high-quality, aluminum stock cosmetics range that uses trendy colored plastic trim as a contrast.

The allure of metal has also led to a key change that will be made to adapt an existing HCP production site in China to concentrate on aluminum components. This new operation will also include a large number of transfer pressing, impact extrusion and automatic anodizing capabilities.

“Aluminum was previously a material not fully integrated in our production program. We saw a real need in the market and as a packaging manufacturer, it was a necessity to offer an integrated solution,” explains Eddy Wu, HCP’s CEO.

Sophisticated Tubes (looking for lipstick tube?)

Tubes have become more prevalent than ever, even for high-end products. Labels, shapes and decorative techniques have risen in sophistication to meet demand.

Coesia’s new Swirl pattern makes tubes stand out. |

Adolfsson says, “Companies mostly come to us asking for help with sealing new tube materials, filling new products, single or multi-color, including our new Swirl pattern.” To help customers with this, Norden (one of Coesia Group’s companies) has a test lab in Kalmar, Sweden, with four to five machines equipped with all the latest features. “This is a unique and valuable service we offer our customers,” says Adolfsson.

How does advanced machinery contribute to innovative packages?

Adolfsson says a couple of things stand out as very helpful. “One is robotic in feed systems since they are as efficient with oval tubes as they are with regular round tubes. The other is our third generation hot air sealing system. With better heat control we are able to seal thinner materials with maintained speeds and appearance.”

Need for Speed (looking for eye shadow case?)

In this fast-paced world, where “new” reigns—and has a shorter lifespan than ever, in part due to the Internet, brands and suppliers face the double edged sword of a product that needs not only to be innovative, but quick to market as well—a dilemma that also requires thinking outside the box—and greater agility, especially on the part of the supplier.

Mintel’s Dr. Punchard notes: “Packaging in beauty has always been fast moving, responding to a market that changes each season, particularly in color cosmetics. However, often this just drives a change in contents rather than in the packaging. I think that increasingly this isn’t enough and to really keep up with fickle consumers we’ll be looking to greater changes on a more regular basis. Fortunately many packagers are becoming more agile and able to cope with rapid changes and short runs and technology that can enable short runs, such as digital print becoming more affordable. Indeed just as brands are being forced into more frequent packaging refreshes, it will be those packaging companies that can offer the greatest flexibility that will gain the greatest spoils.”

Eade, of Kemas USA, says speed-to-market is very important “from the sense of claiming your position as the pioneer or creator of that technology.” That’s because he says, “unfortunately, in today’s extremely competitive world of manufacturing, the moment anyone catches wind of a new idea or concept, you have companies out there that would be more than willing to try and copy or duplicate those ideas.” Therefore, says Eade, the best way to establish your claim to a new innovation is to try and get launched to market in the quickest possible time frame. The downside, he says, “is that very rarely can anyone launch something quickly to market.”

At HCT, Pyrzenski says each program is specific to its own needs, and HCT “works to create the best solutions to meet the demand of an ever-shrinking timeline.” He says as HCT “is fully integrated to offer full turnkey services, this does aid in our ability to deliver when timing is critical.”

Carey of Arkay Packaging, notes: “The development cycle of innovative packaging shortens as our customers’ time lines do. You have to be nimble and responsive.”

Color Optics’ Opti-Glitter process eliminates the need for off line silk screen glitter. According to company president Joe Cicci, it’s an innovative way to get the look and feel of glitter without paying a major upcharge. Color Optics developed the process and is now incorporating it into packaging work. |

Working locally, in close proximity to clients has been an asset for Lombardi Design & Manufacturing. Albanese says, “Our local engineering and production has helped us to offer some of the quickest speed-to-market options to our customers. This has allowed us to offer innovation unhampered by tight launch times. We make it a point to advise on lead times from the outset of a program and closely monitor any changes made by the customer.”

Cosmogen has a different approach. Marketing manager Charlotte Clabaux says the company develops new items all year long and presents them to customers once the package is ready for production. “That means it can be rapidly produced and then marketed,” she explains. Clabaux says another solution is to “adapt and customize already marketed products and to provide them with a specificity that makes it unique.”

Innovation Ahead

What types of innovative packages wait on the horizon? Undoubtedly they will range from simple to complex.

At Kemas, Eades says, “We are working on new developments that we hope will not only change the scope of packaging aesthetics and design in years to come but also enable the brands to open up a whole new range of design opportunities from a marketing perspective. Our focus right now is on releasing new products that can not only be considered ground-breaking, but also revolutionary in the sense that it can potentially change the way we see and feel packaging today.”

Might we see new materials? “Materials are always going to be in the spotlight,” says Eade, but more from an ecological and environmental impact perspective. We’re seeing different materials come and go but for the most part, the industry tends to stay with what it knows works best.”

Mintel’s Dr. Punchard, says, “I think we’ll see a battle between technology (offering convenience and help in getting just the right look, etc.) and artisanal (going retro, old school packs and perhaps a step backwards in functionality). So packaging that can offer functional benefits but without massive technical interventions will do best.”

Brand Innovation

This fall, Chloé took a feature known to nail product packaging and applied it to fragrance, in a limited edition miniature version of its eau de parfum, See by Chloé. See by Chloé Paint a Scent ($39) catches the eye with a bright pink brush inside the silhouette of the bottle. The packaging is intended to create a new perfume ritual, a delicate gesture thanks to the brush, which is used to gently apply fragrance to the skin.

Too Faced answered the call for double-duty beauty products, creating Jingle All the Way, a cosmetic palette that not only looks like an accessory, but functions as one, too. Pop out the makeup palette and use the iPhone 5 case designed by celebrity decorator and TV personality Mary McDonald. The two-in-one iPhone case and makeup palette ($25) includes 11 shadows, a bronzer, and a blush.  |

Beauty Packaging asked some of the suppliers interviewed for this article: Looking back, what was the most innovative package you ever produced? Why? HCT’s John Pyrzenski says the company’s patented cooling tip technology “has been unquestionably the most successful innovative delivery system, with HCT producing over 25 million tips for the industry in 2013 alone.”He adds: “With consumer

HCP’s Sue Pickford says it has to be Stila’s Solar Compact. “This multi-award winning compact is HCP’s most innovative compact to date and credit must be given to Stila for considering the origins and long-term future of their cosmetics products. Solar-powered and fully rechargeable up to a thousand times, no main power supply is required for it to function. The glass solar cell panel has a five-year lifespan and is

Coesia Group’s president, Göran Adolfsson says: “That has to be the Design-A-Seal innovation from Norden. This was the first time in the history of the tube (around 200 years in use) where marketers could choose custom-shaped end seals.” Cosmogen’s Charlotte Clabaux thinks that the Squeeze’n range is the most innovative package Cosmogen has ever produced. She says, “The year 2006 was the early beginning of ‘all-inclusive packaging,’ integrating body and applicator (plus performance of formula). With its experience of application thanks to its brush activity, Cosmogen was a pioneer in the understanding of the strength of application solution. The bottom line is the combination of a tube, a patented open/close rotary head (to preserve formula) and a multi-functional applicator.” The range is now available in three sizes. |

At L’Oréal: Consumers Trigger Innovation

BP: What is the mindset behind creating an innovative product? DW: When discussing packaging innovation, we must look through the eyes of our consumers. As engineers and scientists, we often develop innovative solutions and patentable ideas, but really what matters to the consumer is what he or she perceives as innovative packaging. This often can range from simple but distinct packaging or graphics, all the way to very complex packaging that looks unique and beautiful. At the end of the day, the consumer’s first introduction to a product is critical, and this can be in the form of an advertisement, word-of-mouth, or simply walking down the aisle at the store and seeing a product that looks unique and interesting. BP: What is L’Oréal’s dedication/approach to innovation? DW: At L’Oréal, innovation has always been nurtured by a constant dialogue between science and marketing. It is founded on ever-more precise scientific knowledge of skin and hair around the world, but is also based on attentive listening to consumers on every continent and on the observation of their behavior where beauty is concerned. A true source of inspiration, the great diversity of beauty rituals opens up new fields of exploration.

DW: Maybelline New York recently launched Color Elixir by Color Sensational, a revolutionary creamy lip lacquer. This launch delivers a breakthrough technology, consisting of a trio of concentrates to provide the hypersaturated color of a lipstick, the cushiony care of a balm, and the glass shine of a lacquer. This innovative formula is encased in a sophisticated, prestige-inspired pack that nods to both lip color and lipgloss. The pack features a color-matched lipstick bullet to communicate the rich color experience, but is encased in a crystal-clear shell to communicate the luminous shine. In addition, the twist-off cap reveals a smoothing angora brush that delivers a polished application that almost hugs the lips. BP: How did the idea originate? How did you bring it to fruition? DW: The motivation behind Maybelline’s Color Elixir by Color Sensational was driven by a brand new formula innovation, as described (above). For the product concept, it was critical that we prominently featured a classic lipstick bullet to immediately signify to the consumer that this was not a lipgloss but instead, a brand new lip color product. Additionally, many of the attributes of the formula required specific selection of materials and package design elements that forced us from the beginning to determine the best approach to engineer the package. We defined clear cost parameters early on in order to ensure we could bring this new innovation to the mass market. To balance the various objectives and meet the aesthetic demands, we agreed upon a design that involved a multi-piece bottle consisting of a clear outer bottle, a shade-matched inner bottle that mimicked the shape of a lipstick bullet, and a separate collar that secures the pieces together. (For a video on the development of Color Elixir, please see www.beautypackaging.com/videos) BP: Were there any technical challenges? DW: During the development, we faced several technical challenges that we had to overcome through the engineering of the package: the gate location for the inner bottle; the assembly of the outer bottle, inner bottle, and collar; and selecting the appropriate materials to balance the aesthetic and technical requirements. We worked very early in the development to do various trials with the gate located at the bottom pointed tip of the bullet. Through these trials we were able to optimize the size and location in order to minimize the gate appearance, reduce flow lines, and deliver an aesthetic that looked like a molded lipstick bullet. For the bottle assembly, we engineered a specific welding strategy to hold all three pieces together (inner bottle, outer bottle and collar) while guaranteeing a perfect seal to protect the formula. Finally, we evaluated several materials during the development of this package to ensure we could achieve the aesthetics while also protecting the formula. In the end, we went with a material that was naturally clear and could deliver the colored pigments used to mold the bullet, enabling us to achieve the shade match of the plastic molded bullet to the formula contained inside. We are excited by the final product—by the level of quality and beauty that we are able to bring to the mass market. BP: How does speed to market influence how you work? DW: Speed to market will continue to affect the way we work. L’Oréal is very agile to react to any market changes. What our consumers are looking for in terms of innovative packaging is really a strong differentiation, a compelling visual impact and also an effective functionality and enhancement to formula application. To deliver this perfect equation, we work jointly with Marketing and Research and Innovation, and we also rely on our suppliers for Open Innovation. Our dedication to packaging innovation increases every year and is fueling the pipeline of strong launches for the upcoming two to five years. Often it is not about the speed to market but about being there at the right time for our consumer with the perfect product proposal. |

LinkedIn