2014-02-20 09:34:39

Facilities for Cosmetics Production: Packaging Beauty Efficiently

2014-02-20 09:34:39

By Sascha Rentzing

|

|

Beguiling fragrances, smoothing essences, lipsticks with both decorative and conditioning ingredients—the range of products offered by the cosmetics industry is vast, and the demands made on cosmetics packages are just as diverse.

Customers expect high-quality products that offer beauty, well-being and a certain image. The packaging must be a high-quality eye-catcher with a stylish look and, if possible, be equipped with additional functions.

|

|

However, the rising cost of energy and raw materials makes it difficult to produce lavish cosmetics packaging. Besides, consumers are attaching more and more importance to sustainably produced merchandise. This means that packaging not only has to look attractive, but must be manufactured in a way that is ecologically and ethically acceptable.

This confronts the cosmetics industry with a difficult challenge. It must strike a compromise between luxury and efficiency, so that it can retain its customers while ensuring that costs will not spiral out of control.

Modern production technologies offer a solution. “The trend is moving toward increasingly fast and reliable packaging machines. With their help, manufacturers can reduce their environmental footprint and cut costs at the same time,” says production expert Oliver Bernd of the German Packaging Institute in Berlin.

Cosmetic packaging

Downtime-free Cleaning

Among the newest developments in packaging technologies are the

|

|

piston filling machines of the FLK 8000 CIP Plus series from the German packaging and process specialists Bosch Packaging Technology. Piston fillers are used especially for filling products with liquid, viscous, and paste-like consistencies.

According to Bosch, the FLK increases production efficiency and output and thereby lowers production costs despite rising prices. The new Bosch technology convinced L’Oréal, the French cosmetics group. It ordered this equipment in order to optimize the filling processes for its makeup lines.

“We were looking for a flexible and expandable machine that could be cleaned while it was running,” explains Pascal Sigonneau, who is responsible for machinery sourcing in makeup production operations at L’Oréal. “We finally decided on Bosch, as this was the only manufacturer that was able to offer a highly efficient cleaning process, especially while machine parts are in contact with the product.”

Another advantage of the FLK is that the Cleaning-In-Place process (CIP) is reproducible, which means that it can be repeated as often as required without becoming less effective. Cleaning makeup machines is considered to be especially difficult, because most products contain water-resistant and oily substances which are intended to remain in contact with the skin as long as possible.

L’Oréal previously used manual cleaning processes for

|

|

which certain machine parts had to be dismounted. This resulted in production downtimes that sometimes lasted several hours. The new Bosch line, on the other hand, works with three tanks that are cleaned independently of one another, so that two tanks are in operation at all times. “This eliminates downtime and increases throughput,” says Sigonneau.

No Leak Remains Undetected

The Italian Coesia Group is also pushing ahead energetically with machine innovations. Its Swedish subsidiary Norden Machinery, for example, which specializes in tube filling machines, is constantly at work to increase the flexibility and versatility of its systems. Among Norden’s most recent developments is an inspection system that ensures 100% detection of leaks in plastic and laminate tubes in-line and ejects defective tubes automatically with no interruption in regular product flow.

Process speed thus remains high, and the actual machine output is reject-free, which lowers cost. “There are many inspection systems, but none that enables the 100% result ours provides,” says Hans Söderström, technical director at Norden.

During the process offered by the Swedish company, the tube is filled with the product along with a tracer gas, harmless hydrogen, and sealed. Then slight pressure is applied to the sides of the tube. If even the slightest amount of gas escapes, this is immediately registered by hydrogen-sensing equipment, the heart of the inspection system—and the defective tube is ejected from the production line. Such innovations ensure that high-quality packaging can continue to be manufactured despite the rising cost of energy and raw materials.

China cosmetic manufacturer

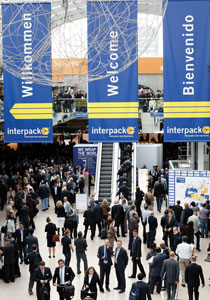

At the Interpack 2014 trade fair, set to take place from May 7 - 14, 2014 in Düsseldorf, Germany, both Bosch and Coesia will be presenting their newest innovations for the pharma and cosmetics industries. In total, almost 900 of the expected approximately 2,700 exhibitors have stated that their portfolios include products and solutions for this target group. ipack11_0158B

LinkedIn