2014-04-15 14:33:37

Elevating Airless

2014-04-15 14:33:37

Airless packages continue to be a highly requested packaging option, suppliers say. In fact, “Airless packages have become somewhat of a status symbol,” says Alexander Kwapis, creative director, Fusion Packaging. “Some products on the market are even starting to mimic the look of an airless package, because consumers are learning about the benefits of airless technology and are demanding it for their products,” he says.

Charlotte Clabaux, marketing manager, Cosmogen, says that brands—and consumers—want more than just a package that will preserve a formula. “Constant innovation is key—and packaging has to be adapted to the application areas to help a formula work better,” she explains.

Vichy Laboratories chose a metal bottle with an airless dispenser shaped with a narrow tip for precise application. |

David Hou, marketing & sales director, Cospack, agrees, saying that innovative designs are necessary, and often requested. “Brands are looking for airless dispensers with distinctive features that stand apart from others on the market,” he says.

Curt Altmann, marketing director, Yonwoo International/PKG Group, says that suppliers are delivering more options. “New shapes and silhouettes are now offering brands even more differentiation—more than just decoration on a cylinder round,” he says.

Functional Innovations Are Key

Achieving higher levels of functionality in airless packaging is a goal for both suppliers and brands, according to Richard Esterbrook, sales manager, The Penthouse Group.

“Our customers are continually developing formulas with very sensitive ingredients that cannot be preserved effectively through conventional packaging. As they push us to develop new containers capable of protecting sensitive formulas from spoilage, hardening, and loss through evaporation, it spurs us to innovate entirely new methods of achieving airlessness in packaging,” he says.

Esterbrook says that this “push” by its customers often makes it possible to be first to introduce a new innovation to the U.S. market. “One recent innovation that we brought to market with Amway is the Yoshino shutoff pump,” he says. “It was extremely successful in Japan, first,” he adds.

The ‘Flip-Top’ Jumbo by Yonwoo International/PKG Group has a unique user-friendly locking mechanism. The airless package was developed for the men’s grooming market. It is metallized PP/ABS. |

Amway’s Youth Xtend Lifting Smoothing Foundation contains this pump, which features a specially designed pintel in the orifice. “As the consumer presses down on the pump actuator, the pintel slides back to allow formula to be dispensed. During dispensing, a mechanism inside the pump maintains a seal to prevent air from contacting the formula inside the bottle,” explains Esterbrook.

Fusion’s Kwapis, has also been seeing a growing interest and more requests over the past year for more functionality in airless packaging, including locking mechanisms.

“To accommodate these requests, we developed the Cirque and T-Lock collections, with locking actuators,” says Kwapis. “These packages do not require an over-cap, so the end consumer can use the products more conveniently, and travel more easily with them. Plus, when a package doesn’t require an over-cap to lock, it can reduce manufacturing and shipping costs,” he says.

PKG Group/YonWoo International, recently developed a metallized cylinder shaped airless package called the Flip-Top Jumbo. “It was designed for the men’s grooming market,” says Altmann. “It has an automatic flip-up nozzle cover on a locking actuator.”

Once the actuator is unlocked with a twist, the nozzle cover automatically opens and closes with each press. “The airless pump also has a product suck-back feature that, together with the nozzle cover, guards against product dry-out in the actuator,” adds Altmann.

Airless with Applicator Tips in New Shapes

Airless pump dispensers are also being paired with applicator tips in new shapes and sizes, and skin care brands are taking advantage. These tips allow a product to be more easily applied to a specific spot on the skin.

In addition to a dispensing tip’s delivery benefits, they’re also eye-catching, user-friendly and can appeal to a younger consumer. Suppliers are offering these tips in a variety of shapes and sizes.

Cosmogen recently launched the Airless Ball, an airless package with a dispensing tip designed to deliver skin care benefits. |

Cosmogen is promoting its Airless Ball—a package with a design that looks futuristic, and appeals to a brand that might want to convey a “scientific” look.

“The applicator has a stainless steel roller ball which allows gentle and cool application to an area. It improves the product application by making small circular movements to help relax, firm, de-puff and cool,” explains Clabaux. “The stainless steel ball delivers an effective mechanical action on the skin that stimulates, cools and relaxes,” she adds.

At the end of 2013, Cosmogen also launched Airless Precision—an airless bottle with a white plastic dispensing tip. “The ergonomically shaped, elongated and flat applicator tip allows precision when applying a formula to any area,” says Clabaux. The tip promotes ease of use with one straight side where it indents, so the user can easily push it to one side to dispense a product.

Vichy Laboratories recently launched LiftActiv Retinol HA Nuit in a metal airless bottle with a multi-directional nozzle, which is a patented design. The tip looks similar to Cosmogen’s Airless Precision, but the one Vichy uses is more rounded—like an upside-down funnel.

The user pushes the nozzle to one side to dispense a precise amount of the

Cosmogen recently launched the Airless Ball, an airless package with a dispensing tip designed to deliver skin care benefits. |

anti-aging product. A white plastic over-cap matches the nozzle’s rounded shape, and screws on to lock closed.

The brand makes sure its anti-aging products are designed with packaging that helps to make using the products more interesting, and fun, for consumers—while protecting its formulations from air and light.(Vichy is also using a metal cooling dispensing tip on one of its products, which is included in a new box designed for the ‘JustBloom’ subscription service. See the Online Exclusive at BeautyPackaging.com)

Elevating the Airless Tube

Some suppliers say that brands are being swayed to switch to airless tubes to reduce costs.

“Our airless dispenser tube provides similar advantages to an airless bottle at half the cost. It’s also compact, ergonomic and compatible,” says Michael Salemi, COO, The Packaging Company. “The pump dispenser also makes it easier to dispense a product from a tube, versus a traditional tube,” Salemi adds.

Fusion’s Kwapis agrees. “Transitioning to airless tubes from earlier atmospheric models is a good way for brands to add metered dosing and give their products a more luxurious appeal.”

Fusion recently launched Tru and Pure airless tubes. “They deflate as they are being used, allowing the handler to see exactly how much product remains, plus they know they are getting every last drop out,” says Kwapis.

Fusion decorated Avon’s Anew Reversalist Firming Serum with a highly reflective red finish. |

ZO Skin Health just re-launched its Ossential Advanced Radical Night Repair anti-aging product, in an airless tube. Since the product retails for $145, it was essential to give the tube a look of“prestige and elegance,” according to Jim Headley, CEO/president, ZO Skin Health, Inc. The tube’s striking blue decoration and silver accents achieved a luxe look. The product contains a full 1% concentration of retinol, so an airless package was essential.

“Retinol is a centric element to our therapeutic skin care regimens, and since it’s sensitive to oxygen, we often use airless packaging to ensure the potency of our products, so the consumer gets the same effectiveness from the first pump to the last pump, ” says Headley.

Aluminum & Metallized Looks

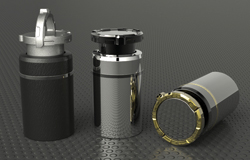

Cospack’s new Agate Airless series of airless dispensing systems, with aluminum over-shells, is available in 15-, 30- or 50ml size bottles. |

Like Zo Skin Health, Vichy chose dark blue for its anti-aging product, which is in a metal airless bottle. Avon chose a highly reflective red that looks metallic.

Do these colorful launches signal a decline in popularity of basic white as a popular choice for an airless skin care package?

According to Fusion’s Kwapis. “We’re seeing a change in aesthetics that were once commonly muted and clinical. Brands such as Avon, Prevage, and Elizabeth Arden have now become brighter and highly decorated,” he says.

Kwapis says in the past, packaging for an advanced formulation had a very simple, clinical aesthetic because decorating processes had not advanced enough to offer more variety. “We made it a priority to develop new ways to protect decorations from advanced formulas, and now we can apply decoration to the inside of a bottle or cap, which gives brands a lot of flexibility with decoration for packages with more aggressive formulas, and there are no adverse reactions,” he explains.

Nest-Filler says its airless ampoule bottles offer one of the safest storage and transport solutions on the market. |

Fusion Packaging worked with Avon to develop the packaging for its product line called Anew Reversalist Complete Renewal Express, which utilizes airless bottles that are decorated with a highly reflective red finish.

The Packaging Company has also developed new proprietary finishes for aluminum airless bottles, in response to trends and requests from beauty brands. “We can combine our finishes with six-color printing,” says Salemi.

For a skin care brand that still wants to use white, one of The Packaging Company’s finishes is a white frost. “In addition to giving a bottle a premium look, the finish also protects the aluminum surface from scratching and chemical abrasion,” says Salemi.

Obagi Medical’s Overnight Repair anti-aging product comes in an aluminum airless bottle with a white finish, produced by The Packaging Company.

Cospack also offers new—and flashy—options in airless packaging. The supplier’s new Agate collection is a series of airless bottles, and a jar, with shiny silver aluminum over-shells.

The packages are entirely encased in an aluminum over-shell fitting—from the cap and pump to the bottle, according to Hou. “The metallic exterior exudes a sense of protection that brands are looking to emphasize, and allows for a wide range of decoration options,” he says.

Airless Ampoules & Syringes

Airless solutions come in all sizes and shapes, including ampoules and syringes.

The Packaging Company recently developed its new Syringe Airless—a bottle with a metal outer spring, to prevent cross-contamination, and an airless pump dispenser. “It functions similarly to a syringe with a targeted applicator tip that delivers a precise dosage of 0.17ml, perfect for pharmaceutical products, serum, and skin care products,” says Salemi.

Nest-Filler is offering new airless ampoule bottles. “They offer one of the safest storage and transport solutions on the market,” says Yoolie Park, director of sales & marketing, Nest-Filler.

The airless ampoules feature an inner container made from tubing glass. “Our ampoules are designed to effectively preserve a formulation under any conditions. They can withstand warmer storage temperatures, as well as more harsh environments, without deforming in any way, which can cause leakage issues,” she explains.

Future Trends

YonWoo/PKG Group’s Altman says the airless packaging industry is headed into a new phase of development. “It’s going to be about more than just sophisticated shapes—its new dispensing options are designed not only for ergonomic ease, but to broaden the range of product formulas that can benefit from airless,” he says.

This year, YonWoo/PKG Group will be introducing its first fine mist airless spray. “Marketers will be able to bring airless beyond creams and lotions,” Altmann says. “Another trend will be the ability to mix a liquid with a powder in one airless system,” he adds.

Suppliers agree that product formulations will continue to become more sophisticated, causing more new developments in airless packaging.

“Airless packaging will continue to advance, to keep up with cutting-edge product formulations—particularly in the anti-aging sector,” says Kwapis. “Brands are investing in expensive ingredients, and they want to make sure the consumer is getting the best formula protection and evacuation rate possible,” he adds.

The Packaging Company’s Salemi agrees, and says he often gets requests for airless packaging that is designed to meet more stringent compatibility requirements—and he expects this trend to continue as formulations advance.

“We have been seeing an increase in requests by customers with formulations that are medically patented, and these products are moving into airless containers that have outer springs and a glass inner ball, as opposed to a stainless steel ball,” explains Salemi. “We have been very aggressive in changing our tooling to meet this feature, and it is offered in most of our airless pumps.”

Kwapis often hears requests from brands to adjust a package design and decoration techniques to accommodate a highly advanced formulation. His words of advice:“Formulators will need to work in tandem with packagers much earlier in the development process to ensure package compatibility and durability for their innovative ingredients.”

LinkedIn